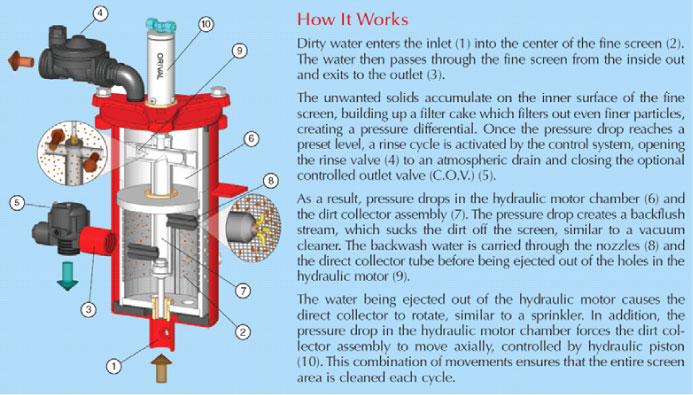

Automatic self-cleaning filters have been developed to displace media tank filtration.

Overview

Let's take a typical case where the flow rate through the system is about 500 cubic meters/hour (2200 gallons/minute)

Typically, for this scenario one would use 10 x 48" sand media filters (picture here) or 3 x 8" automatic self-cleaning filters.

The benefits of automatic self-cleaning filtration are:

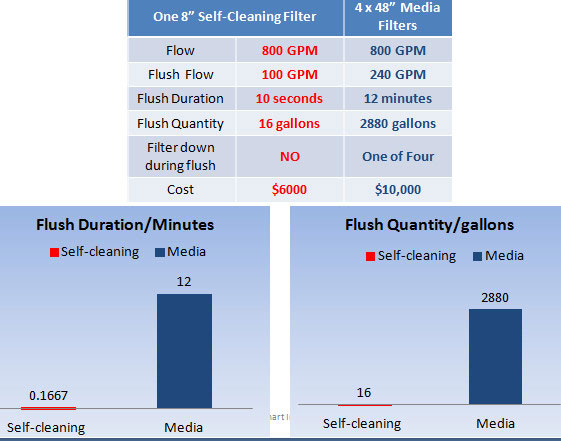

1Flushing rate

A. Each media tank flushes, during the cleaning cycle for 3 minutes at 50 cubic meters/hour (200 gallons/minute). So for 10 tanks the flush rate (wasted water) is 150 cubic meters (600 gallons) x 10=1500 cubic meters (2000 gallons)

B. Each self cleaning filters flushes, during the cleaning cycle, for 10 seconds, each at 12 cubic meters/hour (50 gallons/minute) for a total of 30 seconds or about 5 cubic meters (24 gallons)

C. During the flush cycle, when the media tanks are cleaning themselves they are "off-line" and not providing water to the field. During the flush cycle of the self-cleaning screen filters, at no time, is water diverted from the field

2Degree of filtration

A. During the life of the media filter, while the sand that serves as its medium is of a very high quality and high degree of filtration when new, it quickly degrades and loses its effectiveness as a filter medium over time.

B.The self-cleaning screen filter never loses its quality of filter degree as the porosity of the screen element is static

3Cost:

The cost of three 8" self-cleaning screen filters relative to 10 x 48" media tanks is approximately the same. However the cost of installation, energy, pad required for installation, maintenance and operating costs, make the self-cleaning screen filters much more cost-effective.